-40%

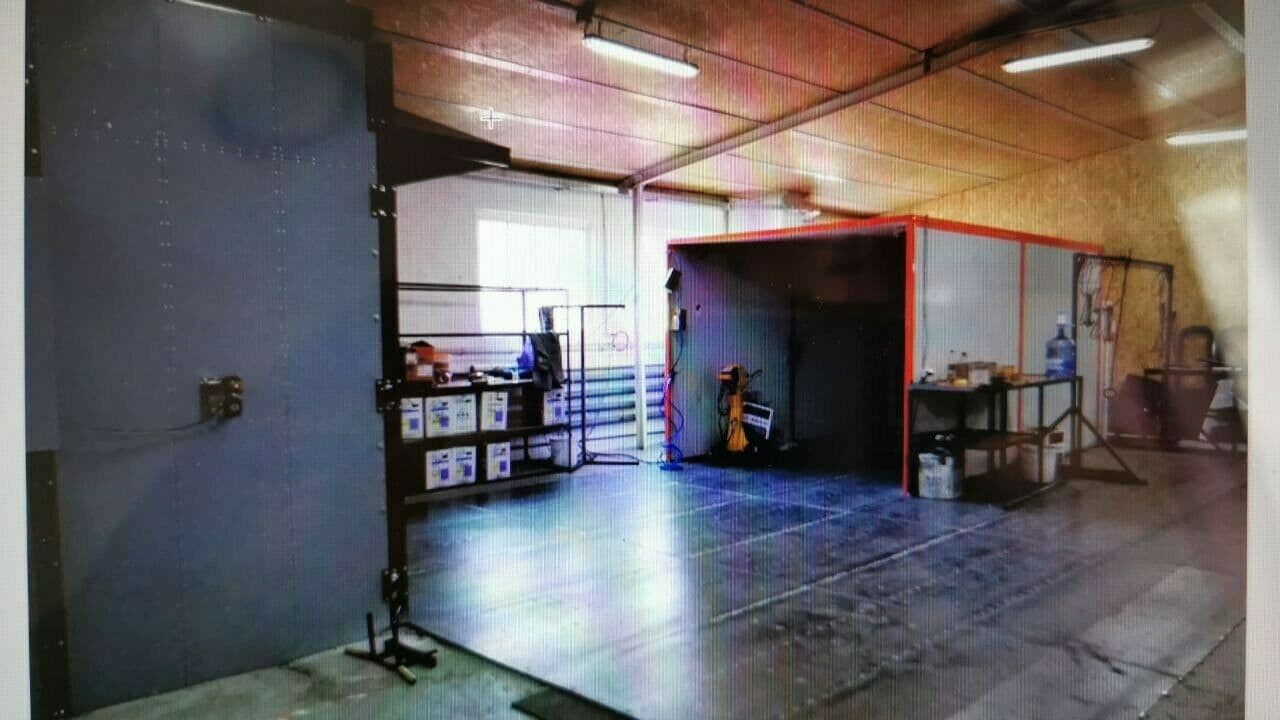

8000 x 3000 x 3000 Full Welded Powder Coating Batch Oven & Polymerization Oven

$ 47520

- Description

- Size Guide

Description

EU CERTIFIEDUSA CERTIFIED

Full Set

1.Complete of the powder coating cabin with the internal size 8000x3000x3000 mm

2.Complete of the polymerization oven with the internal size 7000x 3000 x 3000 mm

3. Ventilation equipment.

4.Scraper floors

Powder coating cabin is open type, equipped with two exhaust ventilation units placed behind the rear wall of cabin.

The dirty air is removed through six cartridges filters installed inside exhaust plenum of ventilation units.

Cabin has the illumination at the top corners and walls (LED lamps, ATEX certificate)

Cabin

Type of the cabin

Quick-mounted

Internal dimension (L x W x H), mm

External dimension (L x W x H), mm

7000 х 3000 х 3000

8000 х 3000 х 3000

Frame

Steel profiles

Walls and ceiling

Sandwich panels (PIR, thickness 50 mm)

Illumination

Light element type

LED (ATEX standard, II3G Ex nA IIC T5 Gc)

Electric power (each unit)

100 W, 24V DC

Quantity

10

Illuminance provided (on the 915 mm from floor)

1000 Lux

LED lamps (Ex), mounted angled to the panels between side wall and ceiling and inside the walls.

Ventilation system

The ventilation system consists from two exhaust units located behind the rear wall of cabin. The ventilation provides the required airflow and high-quality dust removal in the working area of the cabin.

Exhaust unit

Quantity

2

Body

Steel frame covered with powder coated panels

Maximum air flow (each exhaust unit)

14000 m

3

/h

Air flow (working point at static pressure 700 Pa)

7500 m

3

/h

Quantity of fan

1

Fan type

ATEX zone II 3Gc T4 2G

Static pressure

800 Pa

Electric motor

IE3

Power

3,0 kW

Power supply

400V / 50 Hz

Noise level

<75 dB

Total air flow of ventilation system

14000 - 16000 m

3

/h

Total power

2 x 3,0 kW

Air flow speed

0,38 – 0,42 m/sec

Noice level

<75 dB

Filter system

Quantity of cartridge filters per each exhaust unit

4

Filter media

Antistatic aluminazed polyester

Filter’s surface

4 x 20 m

2

Cleaning system of filters

Pulse cleaning with compressed air with economiser

Emission level of dust

Less 3 mg/m

3

CONTROL BOX

Type

Manual and automatic operations

Control type

PLC (Siemens)

Output

LCD touch screen

Working temperature

+ 5 - 25 °С

Total installed power

7,0 kW

Polymerization oven 7000 х 3000 х 3000 mm

Cabin

Type of the cabin

Quick-mounted

Internal dimension (L x W x H), mm

External dimension (L x W x H), mm

7000 х 3000 х 3000

7000 х 5100 х 3500

Frame

Steel profiles

Walls and ceiling

Sandwich panels PIR 50 mm +rock wool 200 mm

Heating system

Gas burner

RIELLO RS 25 M/BLU

Quantity

2

Heat power (min / max each burner)

44/125 – 340 KW

Working power

250 – 260 KW

Heat exchanger

High efficiency, from stainless steel 304

Quantity

2

Air circulation system

The air circulation system consists from four special high temperatured fans located on the side walls of oven. Provides the required airflow in the working area of the oven.

Quantity of fan

4

Maximum air flow

4

x

3690 m

3

/h

Electric motor

IE3

Power

4 x 1,1 kW

Power supply

400V / 50 Hz

Noise level

<75 dB

Total air flow of ventilation system

14000 - 16000 m

3

/h

Total power

2 x 3,0 kW

Air flow speed

0,38 – 0,42 m/sec

Noice level

<75 dB

Transport system

Up rail

3

Load per one rail

500 kg

Control type

PLC (Siemens)

Output

LCD touch screen

Procedure selection

Switch

Working temperature

Up + 230 °С

Heating time up to +180 °С

10 – 20 min

Made in Ukraine

The equipment is delivered under the order within 90 working days, prepayment-50%.

The assembly of equipment is carried out by certified specialists.