-40%

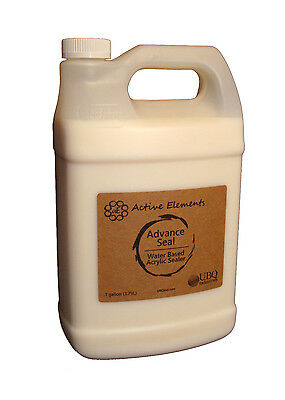

Concrete sealer interior floor sealer water based acrylic sealer 1 gallon

$ 31.66

- Description

- Size Guide

Description

UBQ Industries - Active Elements™ Advance Seal - Interior Concrete Floor SealerWater based acrylic sealer for interior concrete floors •

1 Gallon

Active Elements™ – Advance Seal

is a water-reducible acrylic emulsion based on hard polymers with ultra-small particle size that gives the coating excellent substrate penetration and durability.

The material has excellent UV stability and will not chalk or yellow.

Advance Seal is the perfect solution for interior floors where depth of color and moderate gloss is desired. For added protection on high traffic floors, Advance Seal can be top coated with Active Elements – Protect & Shine to form a sacrificial barrier.

Coverage – 100-200 square feet per gallon

Coverage variations depend on concrete surface porosity and amount of material applied.

Surface Preparation

Concrete must be clean and free of dirt, dust, oil, grease, mold and mildew, and any other contaminants.

Acid Stained concrete must be neutralized, thoroughly cleaned, and dry prior to sealing.

Pigment stained concrete must be completely dry prior to sealing.

Bare concrete and overlays must be open and porous to allow for sealer penetration.

All new concrete should be allowed to cure for a minimum of 45 days, or until a pH reading of 10.5 or less is achieved. Concrete must be completely dry prior to sealer application. It is strongly recommended that a surface probe moisture meter be utilized to verify the surface is dry. After visually determining the concrete is dry, test a minimum of 10 different areas of the concrete with the moisture meter. Pay special attention to cracks, control joints, and slab edges.

Application - Roller

Stir well before use. Pour Active Elements – Advance Seal through a strainer prior to use. Apply by using a high quality 3/8” nap lint free roller cover, or 1/4” nap mohair roller cover (for smooth surfaces). Dip directly into a roller pan and distribute the material by rolling laterally and then up and down (crosshatch rolling). Roll the material into a wet edge, and avoid excessive back rolling. When applying 2 coats of sealer roll the second coat perpendicular to the first. Keep containers closed when not in use, unattended open material will form a skin on the surface.

Application - Sprayer ( HVLP or Airless)

Stir well before use. Pour

Active Elements – Advance Seal

through a strainer prior to use. Spray using an airless or HVLP spray system. When applying 2 coats, spray the second coat perpendicular to the first.

Always use a chemical respirator when spraying with an airless or HVLP spray system. Keep containers closed when not in use, unattended open material will form a skin on the surface.

Drying Time

Dry to touch: 30 minutes

Dry hard: 55 minutes

Recoat: 2 hours

Light Foot Traffic: 4 hours

Full Cure: 72 hours

The listed dry times are for 75 degree (F) temperatures and medium humidity. Low temperatures and/or high humidity will slow drying and curing time.

Clean Up

Tools can be cleaned with soap and water

Performance

% solids by weight – 31% (ASTM D2369)

60 degree gloss – 100% (ASTM D523)

Pencil Hardness – 4B (ASTM D3363)

Flexibility – Greater than 32% elongation (the maximum for ASTM D522)

Impact Resistance – 40 inch-lbs (ASTM D2794)

Abrasion Resistance – Wear index of 0.248, CS17 wheels, 1000g load (ASTM D4060)

Chemical Resistance – 1 hour spot test (ASTM D1308)

Water – No softening, blistering, flaking or discoloration

Detergent– No softening, blistering, flaking or discoloration

Dilute Base (pH13) – No softening, blistering, flaking or discoloration

Dilute Acid (pH2) – Discoloration, but no softening, blistering or flaking

Gasoline– No softening, blistering, flaking or discoloration

Motor Oil– No softening, blistering, flaking or discoloration

Red Wine– No softening, blistering, flaking or discoloration

Ketchup – No softening, blistering, flaking or discoloration

Mustard– Discoloration, but no softening, blistering or flaking

*Performance testing conducted by an independent laboratory.

Limitations

·

Interior use only

·

This product may only be used on fully cured concrete.

·

Not suitable for flooring that is exposed to harsh chemicals.

·

Air and substrate temperatures must be at least 40

°

F and rising.

Storage and Shelf Life

Do not allow to freeze. Shelf life of unopened product is approximately one year.

Slip and Fall Precautions

OSHA and the American Disabilities Act (ADA) have now set enforceable standards for slip-resistance on pedestrian surfaces. The current coefficient of friction required by ADA is .6 on level surfaces and .8 on ramps. UBQ Industries, LLC recommends the use of angular slip-resistant aggregate in all coatings or flooring systems that may be exposed to wet, oily or greasy conditions. It is the contractor and end users’ responsibility to provide a flooring system that meets current safety standards. UBQ Industries, LLC or its sales agents will not be responsible for injury incurred in a slip and fall accident.

Moisture Vapor Emissions/Alkalinity Precautions

All interior concrete floors not poured over an effective moisture vapor barrier/inhibitor are subject to possible moisture vapor transmission and related high levels of alkalinity that may lead to blistering and failure of the coating system. It is the coating applicator’s responsibility to conduct calcium chloride and relative humidity probe testing to determine if excessive levels of vapor emissions or alkalinity are present before applying any coatings.

Warranty

The Manufacturer and/or the Seller warrants that if any goods supplied prove defective in workmanship or material, that Manufacturer and/or Seller shall replace them or refund the purchase price. This warranty is made in lieu of any and all other warranties expressed or implied. Before application, the User shall determine the suitability of the product for his intended use and User assumes all risks and liabilities whatsoever in connection therewith. Under no circumstances shall the Manufacturer and/or Seller be liable for incidental, consequential or other damages for alleged negligence, breach of warranty, or strict liability arising out of use or handling of this product. The sole liability of Manufacturer and/or Seller for any claims arising out of the use or sale of the product shall be for the User's purchase price. Any claim of defective product must be received in writing within one (1) year from date of shipment.

DO NOT TAKE INTERNALLY. KEEP OUT OF REACH OF CHILDREN.