-40%

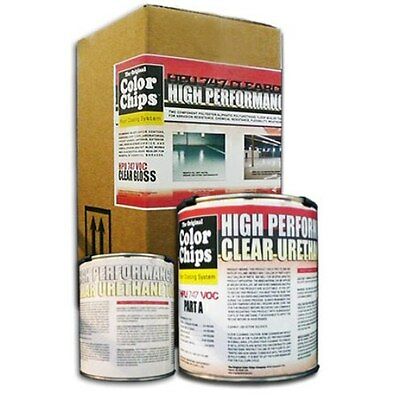

High Performance Urethane - HPU 747- Clear Coat - 1.5 gal. kit FREE SHIPPING

$ 76.55

- Description

- Size Guide

Description

High Performance Urethane Clearcoat kit (500+ sq/ft) 1.5 galOriginal Color Chips High Performance Urethane (HPU 747)

is a clear two component polyester/aliphatic polyurethane floor sealer that exhibits excellent characteristics for abrasion resistance, chemical resistance, flexibility, weathering and UV stability. It is considered a hazardous material therefore can only be shipped via ground transportation (UPS ground only).

When to use High Performance Urethane as a clearcoat:

Used on epoxy color chip floors with a light to heavy broadcast; this thin mil urethane clearcoating will go over the chips and allow the flakes to provide a bit of texture on the floor. HPU is excellent chemical resistance and will not yellow over time (like epoxy). Perfect for giving your epoxy garage floor coating additional chemical resistance and protection.

When NOT to use High Performance Urethane as a clearcoat

: An interior surfaces that exposed flame is present (unless you distinguish flame). HPU emits flammable vapors upon application. It is not recommended for inside buildings/basements, etc. The odor is very strong and

must

be used in a well ventilated area.

Click the following links for more information:

Product Data Sheet

Application Instructions

HPU is also recommended for auto service centers, warehouses, laboratories, aircraft hangers, cafeterias, exterior tanks, outdoor service and chemical exposure areas.

CURE SCHEDULE:

(70°F)

pot life – 1 1/2 gallons volume ...……………………….... 2-5 hours

tack free (dry to touch)…………………………………...…2-4 hours

recoat or topcoat.....…………….…..…………………....... 4-8 hours

light foot traffic...………………………...…………..……14-24 hours

full cure (heavy traffic)…………………..……………...…....3-5 days

APPLICATION TEMPERATURE:

45-90 degrees F

53% (+,-2%)

VOLATILE ORGANIC CONTENT:

Less than 3.8 pounds per gallon

RECOMMENDED FILM THICKNESS:

3-5 mils per coat wet thickness (yields 2-3 mils dry)

COVERAGE PER .75 GALLON KIT:

200 to 300 square feet @ 3-5 mils wet thickness

MIX RATIO:

2 parts A to 1 part B by volume

FINISH CHARACTERISTICS:

High gloss (>80 at 60 degrees @ Erichsen glossmeter)

ABRASION RESISTANCE:

Taber abrasor CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 20.0 mg loss

IMPACT RESISTANCE:

Gardner Impact, direct & reverse = 160 in. lb. (passed)

FLEXIBILITY:

No cracks on a 1/8” mandrel

ADHESION:

360 psi @ elcometer (concrete failure, no delamination)

VISCOSITY:

Mixed = 200-400 cps (typical, most colors)

HARDNESS:

Shore D = 72

PRODUCT STORAGE:

Store product in an area so as to bring the material to normal room temperature before using. Continuous storage should be between 60 and 90 degree F.

PRODUCT MIXING:

This product has a two to one mix ratio by volume- merely mix two gallons of part A with 1 gallon of part B.

After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free.

Avoid whipping air into the coating.

Improper mixing may result in product failure.

PRODUCT APPLICATION:

The mixed material can be applied by brush or roller.

Maintain temperatures within the recommended ranges during the application and curing process.

Properly prime the substrate (with basecoat or other sufficient primer).

It is best to maintain a wet edge to avoid roller marks.

Direct sunlight or high temperatures may cause visible roller marking during application.

Too thick of an application may result in solvent entrapment and product failure.

RECOAT OR TOPCOATING:

Multiple coats of this product are acceptable.

If you opt to recoat this product, you must first be sure that all of the solvents have evaporated from the coating during the curing process.

The information on the front side are reliable guidelines to follow.

However, it is best to test the coating before recoating or topcoating.

This can be done by pressing on the coating with your thumb to verify that no fingerprint impression is left.

If no impression is created, then the recoat can be started.

Always remember that colder temperatures will require more cure time for the product before recoating can commence.

Before recoating or topcoating, check the coating to insure no contaminants exist.

If a blush or contaminants are present on a previous coat, remove with a standard detergent cleaner.

When recoating this product with subsequent coats of the urethane, it is advisable to apply the recoat before 24 hour passes.

Also, it is advisable to degloss the previous coat to insure a trouble free bond.

CLEANUP:

Use ketone solvents (m.e.k..)

Any further questions, comments, or concerns, please feel free to message us. Thank you

- NORKAN INC